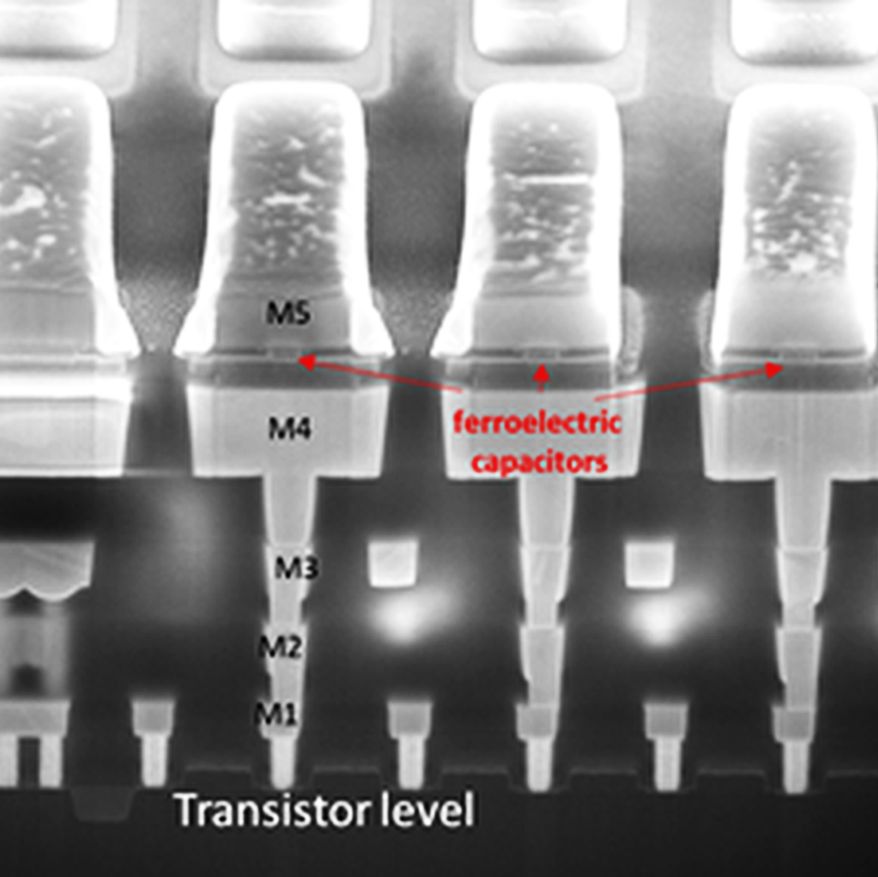

During the last two years the main focus was on the transfer of the metal-ferroelectric-metal capacitor stack with a capacitor diameter of about 100 μm to memory arrays with 100-1000 times smaller feature size. Concurrently, the optimization of the film and film stack properties to improve the reliability of the ferroelectric capacitor according to industry specifications was addressed. The goal is to develop a back-end-of-line (BEOL) compatible capacitor structure with a maximum thermal budget below 500°C. The ferroelectric material of choice is an atomic layer deposited Hf0.5Zr0.5O2. Development on the topic was carried out with industry partners like LETI, ST within a European project ‘3eFerro’ and Sony.

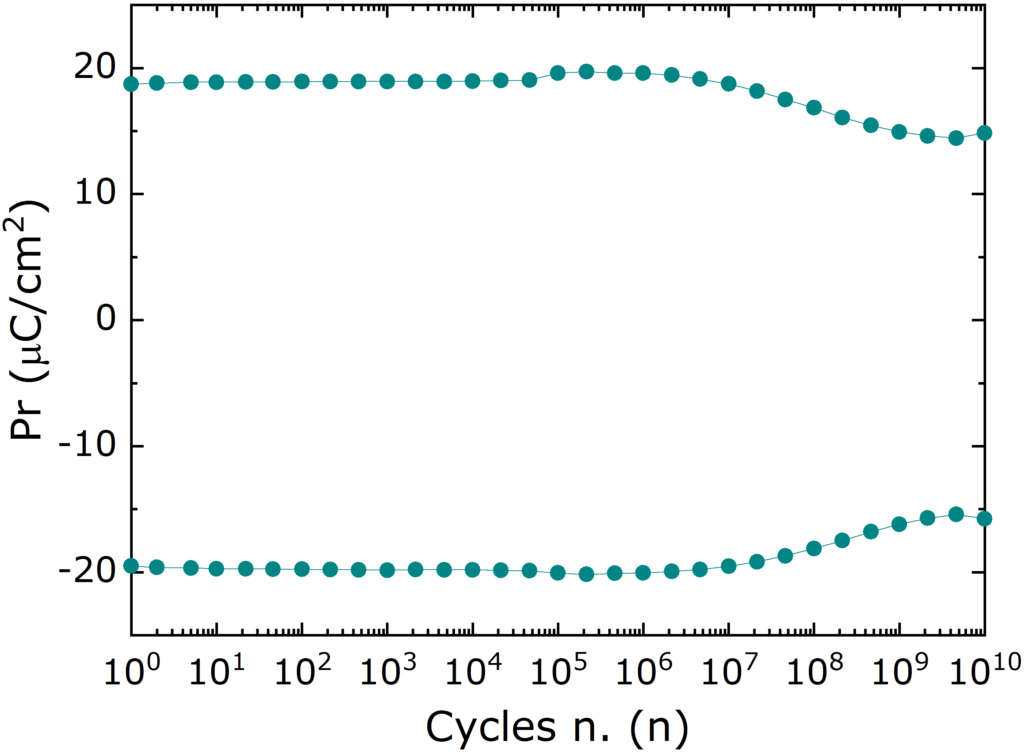

The polarization hysteresis of a Hf0.5Zr0.5O2 based capacitor showed a maximum remanent polarization value of about 25 μC/cm². In addition, the influence of Lanthanum doping in Hf0.5Zr0.5O2 on the field cycling behavior was examined and a stable cycling behavior up to 1E10 cycles was achieved (Figure 1). Wake-up, internal bias fields, fatigue, imprint and retention effects in Hf0.5Zr0.5O2 are generally dominated by charge trapping effects at defects mainly located in the Hf0.5Zr0.5O2/electrode interface. Furthermore, depolarization effects can be caused by non-polar phases. Structural changes associated with field induced phases transitions are determined to be highly suppressed with less than 1 % changes in synchrotron-based diffraction measurements. The length of the oxidant pulse within the atomic layer deposition process plays a major role in the phase formation and the reliability properties of the capacitor structure (Figure 2). The duration of the ALD oxidant pulse strongly impacted the ferroelectric properties and an optimum process condition could be determined. Switching characteristics beneficial for non-volatile memory applications were then evaluated with optimum ferroelectric properties. Due to the resulting voltage-time trade-off to achieve > 90% domain switching after 10 ns, a voltage of about 2.5 V has to be applied to 10 nm thick films.

Fig. 1: Remanent polarization values for ~10 nm thick Hf0.5Zr0.5O2 based capacitor during field cycling.

Fig. 2: Remanent polarization for HfxZr1-xO2 films with different oxidant dose times in capacitor structures with TiN electrodes.

Both development partners introduced the Hf0.5Zr0.5O2ferroelectric material into their memory arrays and reached a field cycling endurance > 1011 for sub 1 μm capacitor structures (Figure 3), good read voltage margin at 2.5 V operation voltage and confirmed an operating speed of about 10 ns for memory arrays of 16 or 64 kbit.

Future studies will focus on further understanding of the structural basis of the ferroelectric properties and their impact on the ferroelectric switching behavior, with the goal of improving cycling performance for introduction into larger memory arrays.

Cooperation:

CEA Saclay / CEA-LETI (France), ST Microelectronics (France), National Institute of Materials Physics (Romania), EPFL (Switzerland), Ecole Centrale De Lyon (France), NCSR „DEMOKRITOS“ (Greece), Forschungszentrum Jülich (Germany), Sony (Japan)